Introduction

Laboratories are critical environments for research, development, and quality control across various fields, including healthcare, pharmaceuticals, environmental science, and education. The effectiveness and accuracy of laboratory operations heavily depend on the quality of laboratory equipment and the processes involved in its supply, installation, and calibration. This blog post explores the importance of these aspects and how they contribute to successful laboratory operations.

Understanding Laboratory Equipment Supply

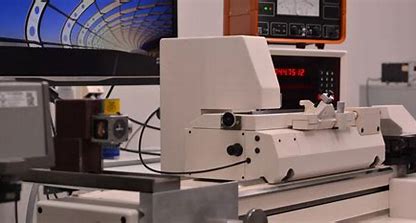

Laboratory equipment supply encompasses the procurement of essential tools and instruments needed for scientific work. This range includes basic items like beakers and pipettes to advanced machinery such as spectrophotometers, chromatographs, and centrifuges. The supply process involves several key considerations:

1. Quality and Reliability

The reliability of laboratory equipment is paramount. High-quality instruments ensure accurate results, which is crucial for research integrity and safety. Suppliers must provide equipment from reputable manufacturers known for their durability and precision.

2. Variety and Specialization

Different laboratories have unique needs based on their specific applications. A robust supplier offers a wide range of products, from general laboratory supplies to specialized equipment tailored to particular scientific disciplines. This variety allows laboratories to find the exact tools they need for their work.

3. Technical Support and Training

Suppliers should also provide technical support and training for laboratory staff. Understanding how to operate equipment correctly is essential for achieving reliable results. Training sessions can cover equipment usage, maintenance, and troubleshooting, empowering laboratory personnel to maximize the effectiveness of their tools.

Installation of Laboratory Equipment

Proper installation of laboratory equipment is crucial for ensuring optimal performance and safety. This process typically involves several steps:

1. Site Assessment

Before installation, a thorough assessment of the laboratory space is conducted. This includes evaluating the layout, electrical requirements, plumbing needs, and safety considerations. Understanding the physical environment helps ensure that equipment is installed correctly and functions as intended.

2. Professional Installation

While some laboratory equipment can be installed by in-house staff, complex machinery often requires professional installation. Experienced technicians can ensure that equipment is set up according to manufacturer specifications, minimizing the risk of operational issues.

3. Safety Compliance

Installation must adhere to safety regulations and standards. Proper placement of equipment, along with adequate safety measures (such as emergency shut-off switches, ventilation systems, and protective barriers), is essential to maintain a safe working environment.

Calibration: Ensuring Accuracy and Precision

Calibration is a critical process that ensures laboratory equipment operates within specified tolerances, providing accurate and reliable results. This process involves adjusting and documenting the performance of instruments against known standards. Here’s why calibration is essential:

1. Accuracy of Results

Inaccurate measurements can lead to erroneous conclusions, which can have serious implications, especially in fields like healthcare and pharmaceuticals. Regular calibration helps maintain the accuracy of equipment, ensuring that test results are trustworthy.

2. Regulatory Compliance

Many industries are subject to strict regulations that require regular calibration of laboratory instruments. Compliance with these regulations not only safeguards the integrity of research but also protects organizations from legal and financial repercussions.

3. Extended Equipment Lifespan

Regular calibration can help identify potential issues early, preventing equipment malfunctions and extending the lifespan of instruments. By maintaining equipment in optimal condition, laboratories can reduce downtime and operational costs.

4. Standard Operating Procedures (SOPs)

Integrating calibration into standard operating procedures is crucial for maintaining consistent practices within the laboratory. SOPs should outline the calibration schedule, methods, and responsibilities, ensuring that all staff are aware of the importance of this process.

The Supply Chain: From Procurement to Calibration

The supply chain for laboratory equipment involves several interconnected steps:

1. Procurement

Choosing the right supplier is the first step. Laboratories should seek suppliers with a proven track record of quality, reliability, and customer service. Researching suppliers, reading reviews, and requesting quotes can aid in making informed decisions.

2. Installation

Once equipment is procured, the installation process begins. As mentioned, this may involve site assessments and professional installation. Clear communication with the supplier is essential to ensure that all requirements are met.

3. Calibration and Maintenance

After installation, establishing a calibration schedule is crucial. Laboratories should maintain records of calibration dates, results, and any maintenance performed. Regular audits can help ensure compliance with industry standards and regulations.

4. Training and Support

Ongoing training and technical support from suppliers are vital for laboratory staff. As new technologies emerge, staying updated on best practices and equipment usage is essential for maintaining a high standard of work.

Challenges in Laboratory Equipment Supply and Calibration

Despite the importance of laboratory equipment supply, installation, and calibration, several challenges can arise:

- Budget Constraints: Limited budgets can hinder laboratories from acquiring the latest and most reliable equipment. Organizations must balance cost with quality to achieve optimal results.

- Rapid Technological Advances: The fast pace of technological innovation can make it difficult for laboratories to keep their equipment up to date. Regular training and supplier support can help address this issue.

- Regulatory Changes: Changes in regulations can impact calibration standards and requirements. Laboratories must stay informed and adapt their practices accordingly to maintain compliance.

Conclusion

The supply, installation, and calibration of laboratory equipment are critical components of successful laboratory operations. By ensuring the quality and reliability of instruments, adhering to safety regulations, and maintaining accurate measurements through regular calibration, laboratories can enhance their efficiency and effectiveness. As the scientific landscape continues to evolve, investing in high-quality equipment and robust support systems will be essential for fostering innovation and achieving reliable results in research and development. By prioritizing these aspects, laboratories can not only improve their operational standards but also contribute to advancements in science and technology that benefit society as a whole.

No responses yet